High-quality cast iron rotary axis for CNC milling machines. It is suitable for processing steel, cast iron, aluminum and other non-ferrous metals, plastics as well as wood and other related materials. The control can take place in the indexed mode or with smooth simultaneous interpolation. The axle is available with a tailstock. Supplied as standard with a 125 mm diameter three-jaw chuck.

A set of posts placed around the machine to detect the presence of people approaching it. They cause the device to stop working when the laser beam is exceeded. The set consists of a transmitter, a receiver and two reflecting mirrors, which ensures the machine is secured up to three sides. Contrary to laser barriers, they have more densely placed laser beams, which enable faster reaction to human intrusion into the machine's operating zone.

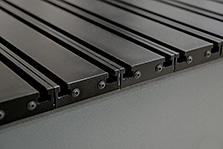

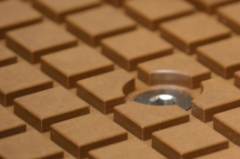

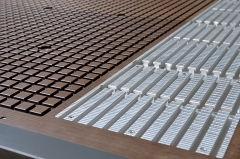

A set of mechanical bases placed on the machine table, ensuring repeatability of the arrangement of the given material (usually boards). The operator, when placing the material on the table, pushes it against the protruding pins, thanks to which it is placed in the right place. This solution helps with high-volume production of components...

This head is characterized by a very high oscillation force. Thanks to this, it is possible to cut through materials that offer very high resistance, as well as materials with a large thickness. With the use of an appropriate blade, it is possible to cut rubber with a thickness of up to 30mm. The oscillation speed is regulated by setting the desired value from the program in the range from 0 to 5000 movements per minute. If the value is set to 0, the blade automatically moves to the maximum forward position and the head performs work without oscillation. A speed range of around 1000 strokes per minute is typically used.

Usually mounted horizontally under the machine gate. It can contain from a few to a dozen or so sockets for CNC tool holders. Tool change is faster than in linear magazines due to the shorter travel time to the tool change point.

The touch scanning head is used, inter alia, to scan details in order to make duplicates or enter into the computer memory for further processing. It allows you to scan uneven surfaces and take into account its deflection when designing. It can also be used as a probe for basing on plates, in holes, on cylinders and for scanning three-dimensional objects for digitization. It is available in a wired version - manually mounted, lowered automatically on the Z axis and in a wireless version - taken from the tool magazine.

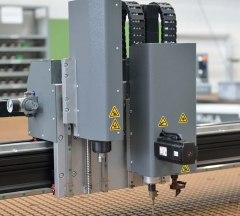

Functionality that allows you to automatically change the tool used for machining (cutter, drill, head, etc.). The tool is placed in a special holder (cone), which is picked up by the machine spindle from the tool magazine (linear or rotary). Thanks to this solution, there is no need to stop machining and change the tool manually in the spindle.

System of minimum lubrication with air-oil mixture fed to the cutting zone. It replaces the traditional, uneconomical cooling systems of the treatment zone based on emulsion solutions. Before the outlet nozzle, the air supplied under pressure mixes with the oil dosed in the volume of a few drops per minute. Lubrication of the cutting zone...