The tool correction sensor enables automatic input of the tool length correction value mounted in the CNC chuck or directly in the spindle. The machine tool automatically measures the length of the tool, then corrects the Z axis coordinate so that the end of the tool is at the appropriate height. In machines equipped with an automatic tool change, the measurement may be performed once or before each use. It is also possible to measure the tool after machining to check for damage.

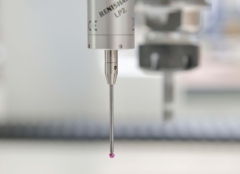

The touch scanning head is used, inter alia, to scan details in order to make duplicates or enter into the computer memory for further processing. It allows you to scan uneven surfaces and take into account its deflection when designing. It can also be used as a probe for basing on plates, in holes, on cylinders and for scanning three-dimensional objects for digitization. It is available in a wired version - manually mounted, lowered automatically on the Z axis and in a wireless version - taken from the tool magazine.

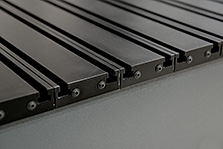

System of minimum lubrication with air-oil mixture fed to the cutting zone. It replaces the traditional, uneconomical cooling systems of the treatment zone based on emulsion solutions. Before the outlet nozzle, the air supplied under pressure mixes with the oil dosed in the volume of a few drops per minute. Lubricating the cutting zone with such a mixture is very effective, in addition to increasing machining efficiency and extending the tool life, it ensures cleanliness in the manufacturing environment. Start and stop of cooling are controlled automatically.