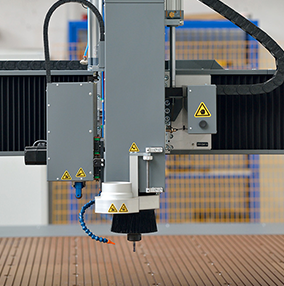

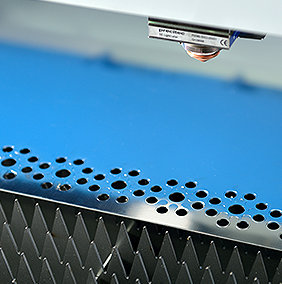

Laser fiber cutter

Our new laser fiber with linear drives, enables quick and efficient cutting of any shape out of sheet metal. Our lasers are extremely high speed up to 5 m/s and fast acceleration. This power combined with a high resolution measurement systems we achieve extraordinary efficiency and cutting accuracy.