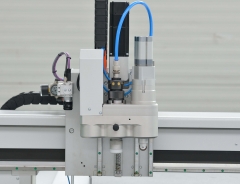

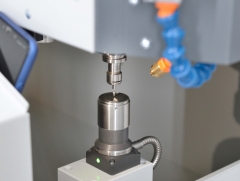

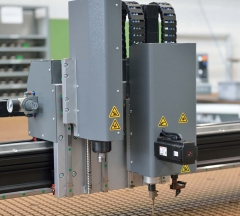

This functionality allows for automatic change of the tool used for processing (milling cutter, drill bit, head, etc.). The tool is placed in a special holder (cone), which is taken by the machine spindle from the tool magazine (linear or rotary). Thanks to this solution, there is no need to interrupt the machining and manual change of the tool in the spindle.

Placed on an aerial arm and attached to the CNC machine, the panel replaces the existing solution in the form of a control cabinet and has a more ergonomic construction in relation to it. The desktop includes an industrial PC computer which is the interface of the machine, along with a monitor, keyboard, and mouse, while the electronics, in this case, are transferred to an electronics control cabinet in the back of the machine frame.

A control cabinet with a control panel adapted to a given machine, equipped with a functional drawer for small CNC accessories, tools, wrenches, etc. Airtight construction, ventilated, made of 1.5 mm thick sheet steel powder coated. Installed locking wheels to allow you to adjust the position of the desktop within a few meters to set up the machine and provide ergonomic position. In other words the control cabinet on wheels to allow for the operator to move the cabinet around in different positions to suit his needs.

A set of light posts positioned around the machine, detecting the presence of people going through them. They stop the operation of the device after exceeding the laser beam. The set consists of a transmitter, a receiver and two reflective mirrors, which ensures protection of the machine from three sides. since they are multi beamed, this allows for faster reaction and detection of a person or object in the machine danger zone.

It is a hypertensive device used for the local removal of fine chips or dust generated during the technological processing of, among others, wood, leather, textiles, plastics, etc. materials. In one common housing, there is a transport fan, a simplified cyclone, and a dust collector. The casing is placed on a mobile base that facilitates the movement of the dust collector. The dust collector is equipped as standard.

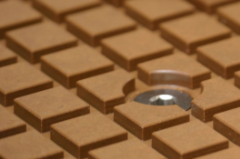

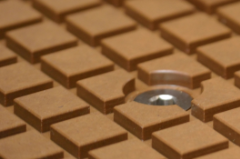

A set of mechanical bases placed on the machine table, ensuring reproducibility of laying the material (usually plates). The operator, when placing the material on the table, slides it up against protruding pins, so that the material is placed in the right position each time in reference to the program.

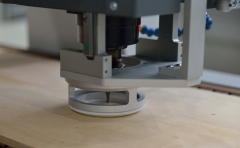

This head is characterized by a very high oscillation force. Thanks to this, it is possible to cut materials with very high resistance, as well as materials with a high thickness. Using a suitable blade, it is possible to cut up to 30mm thick rubber. Oscillation speed adjustable ..