Additional fourth controlled axis. The spindle is tilted around the Y-axis in the range from -95 to 95 degrees. It allows the spindle to be tilted, which allows, for example, for machining side walls of profiles or complex door treatment. This axis is controlled in an indexed manner or with smooth simultaneous interpolation.

Creasing head used with the cutting head (electric or pneumatic), allowing for making special presenting creases, mostly on paper, to enable subsequent folding of the material. Typically, the head uses creasing wheels, with different diameters and widths, as well as other tools, eg V-cut heads.

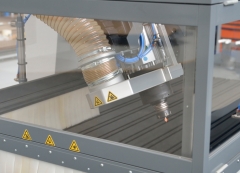

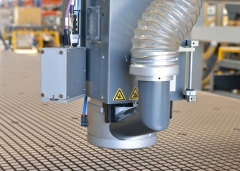

Spindle cover mounted on the Z axis. Its task is to reduce dusting and extract the chips generated during machining. Particularly useful when working in wood and wood-like panels as well as glass-epoxy laminates. Reduces dust, which improves working conditions and increases service life.

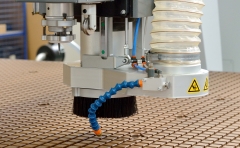

Minimum lubrication system with an air-oil mixture supplied to the cutting zone. It replaces traditional, uneconomical cooling systems for the treatment zone based on emulsion solutions. In front of the outlet nozzle, air is mixed in under pressure with oil dispensed in a few drops per minute. The lubrication of the cutting zone with such a mixture is very effective, in addition to increasing the machining efficiency and increasing the tool life, it ensures the maintenance of cleanliness in the manufacturing environment. The cooling activation and deactivation is controlled automatically.

It is in the form of a bar and is usually mounted on a machine tool table. It works with spindles equipped with the possibility of automatic tool change. It may contain from a few to several dozen sockets for CNC tool holders. The standard solution on the BPF series machines includes ten tool holders.

Usually mounted horizontally under the machine gate. It can contain from a few to a dozen or so sockets for CNC tool holders. Tool change is faster than in linear magazines due to the shorter travel time to the tool change point.